SAR INDUSTRIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SAR INDUSTRIES

Flexographic Manual Printing Machine

mprising of:

Electric Motor: 1hp/2hp/3hp / 1440 rpm 3 phase / 50 cycle coupled with reduction gear V-belt pulleys, chain wheels, chain tightening device, chain cover, gear wheels (hov cut) and covered,

Separate chambers with cover for different colors, C.I. side bracket, bearing housing with heavy duty ball bearings to hold main drum duly grinded and hard chrome,

Eccentric bearing housing with self aligned bearings to hold two neoprene coated M.S. Shells for transferring color to stereo, with color tray & cover,

Guide rolls made of seamless pipe duly turned. Roll beneath the main drum fitted with pressure releasing system and operational from feeding end,

Gears made of cast iron except that of mild steel for driving main drum and are hov cut,

Conveyor belts of rubber coated endless to carry printed bags from one end to the other with belt tightening arrangement,

Front platform with laminated sheet complete with margin setter &

One ON / OFF Switch and a set of spanner.

Semi Automated Hydraulic Bale Press

Salient Features:

Four open guide pillars + four guide rode for support of moving platen resulting in perfect alignment and safety of the hydraulic seals.

Hydraulic double acting cylinder.

Slits on both axes provided for the perfect bale strapping.

The moving Platens can be stopped by means of height adjustable limit switches on both sides, i.e. upwards & downwards

Pressure relief valve is providing for overpressure safety.

Available in a wide range of platform sizes, height & tonnage.

Warranty against proper usage on all machine parts for 1 year from the date of delivery.

Hydraulic Cheese Pipe Straighter

Description / Specification of Hydraulic Cheese Pipe Straighter

We are involved in offering a wide range of Hydraulic Cheese Pipe Straighter to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Hydraulic Cheese Pipe Straighter. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

On Line Flexographic Printing Cutting Machine

Description / Specification of On Line Flexographic Printing Cutting Machine

We are involved in offering a wide range of On Line Flexographic Printing Cutting Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of On Line Flexographic Printing Cutting Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Infra Red Lamp

Sar Industries is always in the forefront to innovate solutions to many a problem that HDPE/PP bag manufacturers / printers face. A major problem the printers have to overcome was high drying time for ink printed on bags. Un-dried bags when bundled would spoil the backside of the bags with inks impressions which cause of high ratio of rejection by the ultimate customer. With abundant order in hand and slow drying process they find difficulty in meeting their production target. We then came with an idea of installing Infra-Red Lamp of 1000W, 240Volts capacity to bring down the drying time from minutes to seconds. These Lamps fitted at the delivery end of the printer provide spot heat up to350’C and when it focuses on the moving bags they get dried swiftly. We have offered this to our valued customers who have appreciated our suggestion, which helped to improve their production as the drying time has been brought under control with just one unit of electricity an hour or so.

Mixing Machine

We are very pleased to introduce yet another innovation to woven sacks industry. It will certainly minimize your problems in mixing of raw materials perfectly.

The salient features of our mixing machine are:

1. Reduction of man power working

2. Reduction of mixing time

3. Reduction of mishandling

4. Improves quality of end product

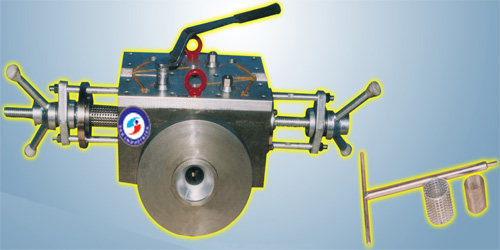

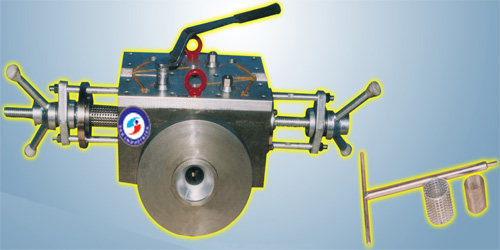

Online Screen Changer

Advantage [Manual to Self Cleaning]:

Absolutely eliminated leakage problem

Absolutely eliminated ideal time

Maximum utilization of tape plant

Elimination of material wastage (Due to nonstop of line)

Easy to Operate

Use any type of CaCo3 and up to 20%

In Self Cleaning Continuous Screen Changer, Screen will be changed after 15 days.

Six Station Cutters

Advantage [Single Station to Six Satiation Cutter]:

Absolutely eliminated ideal time

Maximum utilization of tape plant

Easy to Operate

In Six Station Cutter, Blades will be changed after 6 days.

Payback:

A. Power Saving:

In each stoppage it takes minimum of

20 minutes to stop + 60 minutes to change blade + 20 minutes to start

= The total time is 100 minutes

In whole of this time total system is ON means power loss is

60 minutes of working load

= 150 Units

[Power Saving Per Month =150 Units X 30 = 4500 Units]

B. Production Enhancement:

If we don’t stop the plant twice in day we will get minimum one-hour production more.

One hour production = 150 ~200 Kg.

Hence, the payback period is only 2-3 months.

Six Station Cutter Consisting:

Powder coated cutter assembly

Cutter frame with cover & one roller

One set of shaft

Spacer duly assembled with super max blade

Cutter Stand

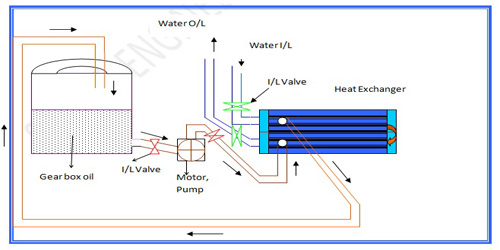

Gear Box Cooling System

You are aware that Gear Box is a very important part of the Tape Plant. Very often the excess heat generated by gears cause its expansion, consumption of excess power and more expenditure on cooling oil. We in SAR INDUSTRIES has innovated a solution to reduce the heat so generated by a method of using an external cooling system to Main Gear Box at a very reasonable cost.

This will ensure increased life to your Gear Box and also Gear Oil. The Gear Box Oil which reaches above 70’C due to continuous running of the plant has to be brought down to a minimum to safeguard the gear as well as gear oil. In a Cooling System that we offer, the oil in the gear box with high temperature is taken out to heat exchanger tank having lines of water circulation pipe from a chilling plant.

The motor-pump combination attached on the oil circulating system pushes the oil via heat exchanger to gear box. The process ensures the gear oil to maintain a temperature between 45’C – 55’C which is safe for the gear system.

Online Pipe Cleaning Machine

Description / Specification of Online Pipe Cleaning Machine

We are involved in offering a wide range of Online Pipe Cleaning Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Online Pipe Cleaning Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Online Stitching Machine

Description / Specification of Online Stitching Machine

We are involved in offering a wide range of Online Stitching Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Online Stitching Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.